The semi-automatic switching device is applied to the depressurization and gas supply of bilateral high-pressure gas cylinders, achieving continuous gas supply through automatic switching, with blowing function. It is widely used in fields such as semiconductor and electronics, medical, genetic technology, biopharmaceuticals, and scientific research. Automatic switching is an open panel used for controlling the transportation of ordinary, inert, and bulk gases. All centralized gas supply systems are very suitable for selecting automatic switching panels.

Continuous gas supply is absolutely necessary in some critical manufacturing and laboratory processes. Suspending gas supply in any way can lead to experimental failure or destruction, loss of productivity, and even downtime of the entire facility. The semi-automatic switching system can switch between the main or backup gas cylinder without interrupting the gas supply, thereby minimizing costly downtime. Once the main gas cylinder or cylinder group is depleted, the system will automatically switch to the backup gas cylinder or cylinder group for continuous gas flow. Then the user replaces the air cylinder with a new one, while the gas still flows out from the reserve side. Bidirectional valves are used to indicate the main or backup side when replacing gas cylinders.

Below is an introduction to the installation method of the semi-automatic gas cylinder switching device

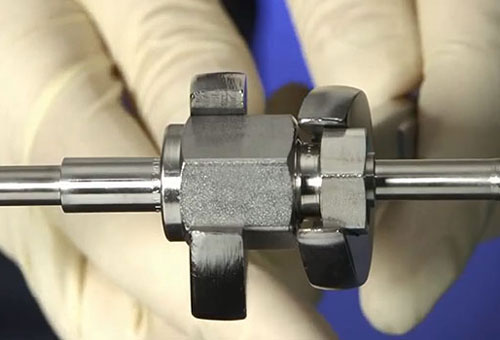

1、 The semi-automatic gas cylinder switching device is installed on the gas cylinder or on the piping.

1. Confirm whether the gas cylinder or piping used is the gas specified in the product manual.

2. Confirm whether there is dust and debris on the outlet of the gas cylinder valve or the sealing surface of the installation pipe used. If there is, please remove the dirt.

3. For products that require the installation of gas cylinder gaskets, it is necessary to confirm whether the gaskets can seal, and then use tools to install them on the gas cylinder or piping.

2、 Semi automatic gas cylinder switching device for gas pressurization

1. Confirm whether the wrench of the adjustable pressure reducer at the upper end is in a non tightened state. If the pressure regulator wrench is in a tightened state, please adjust the wrench to a relaxed state. Check if the shut-off valves on the left and right gas cylinder groups and pipelines connected to the "AGC" semi-automatic gas cylinder switching device are tightened. If the wrench is in a relaxed state, please adjust it to the locked state.

2. Do not stand in front of the semi-automatic gas cylinder switching device. When opening the valves of the gas cylinder and pipeline, be careful to operate slowly. First, open the main gas supply bottle valve and shut-off valve on the left side one by one for the product.

3. There should be no air leakage at the intake joint.

3、 Semi automatic gas cylinder switching device for gas supply regulation

1. Adjust the outlet pressure. When confirming that the left main gas supply cylinder group and the right backup gas cylinder group are in the gas supply state, ensure that the switch handle of the pressure reducer C on the right side of the switching device is on the main gas supply side. Adjust the adjustable pressure reducer A on the upper end of the adjusting device, slowly rotate the pressure wrench in the clockwise direction, and adjust the outlet pressure to the product use pressure. At this point, it is necessary to confirm whether there is any air leakage in the safety valve, pressure regulator housing, and outlet connection to the machine.

When the gas on one side of the current gas cylinder manifold is used up, it can automatically switch to the opposite direction for gas supply.

When the main gas supply bottle is about to run out (>1MPa) and needs to be replaced, slowly rotate the switching wrench of the pressure reducer C on the right side of the switching device clockwise by 180 ° to place the handle on the side of the gas supply. After confirming that the backup gas cylinder group is supplying gas to the system normally, the main gas cylinder group can be cut off and the gas cylinder can be replaced.

After replacing the main gas supply cylinder group, open the valves of the gas cylinder and pipeline, and slowly rotate the switching wrench of the pressure reducer C on the right side of the switching device counterclockwise by 180 °. The switching handle of the pressure reducer C on the right side of the switching device is located on the main gas supply side, and the main gas supply cylinder group can supply gas to the system.

When it comes to gas control systems, every good solution is customized through in-depth communication. Gesparker designs special configuration plans based on the gas demand, gas characteristics, environmental requirements, and other conditions of the gas user. Gasparker, with 13 years of industry experience, introduces various system configurations and product components in the special gas system. Understanding the subtle differences in various system configurations and equipment components can help gas units improve safety, save resources, increase normal operation time, and ultimately reduce costs.